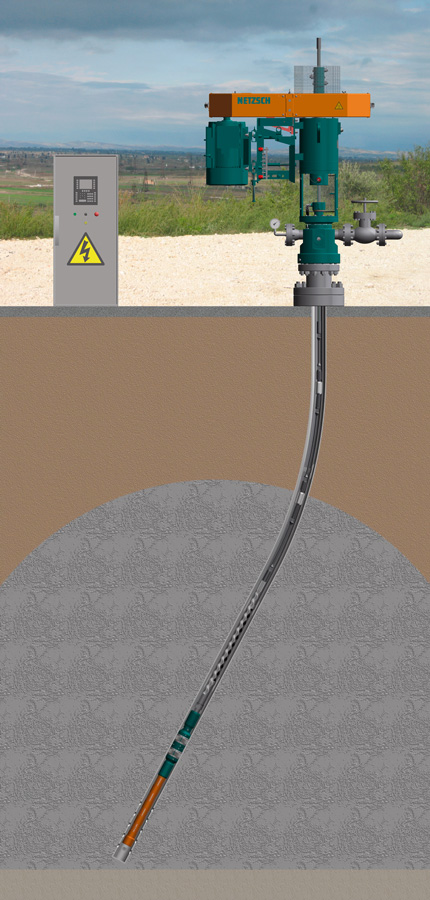

Progressing Cavity Pump System

Efficient handling of fluids:

- High viscosity oil – more than 50.000 cP at the well head

- High sand content – up to 40% at the suction side

- High gas content – app. 40% free gas at the suction side

- Water cut – up to 100%

- Temperature – up to max. 160°C

- Pressure – up to 300 bar

- Production – up to 300 m³/day (1900 bpd)

- Density – up to 0,82 kg/dm³ (45° API)

Key Advantages

- Lower operating cost

- Easy production control

- Energy saving

- Highest safety standards

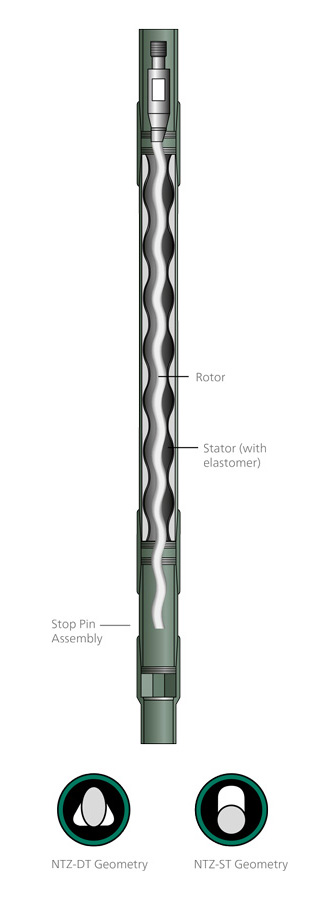

NTZ Progressing Cavity Pumps (PCP)

Efficient handling of fluids:

- High viscosity oil – more than 50.000 cP at the well head

- High sand content – up to 40% at the suction side

- High gas content – app. 40% free gas at the suction side

- Water cut – up to 100%

- Temperature – up to max. 160°C

- Pressure – up to 300 bar

- Production – up to 300 m³/day (1900 bpd)

- Density – up to 0,82 kg/dm³ (45° API)

Key Advantages

- Lower life cycle cost

- Easy installation and transport

- Less number of wear parts

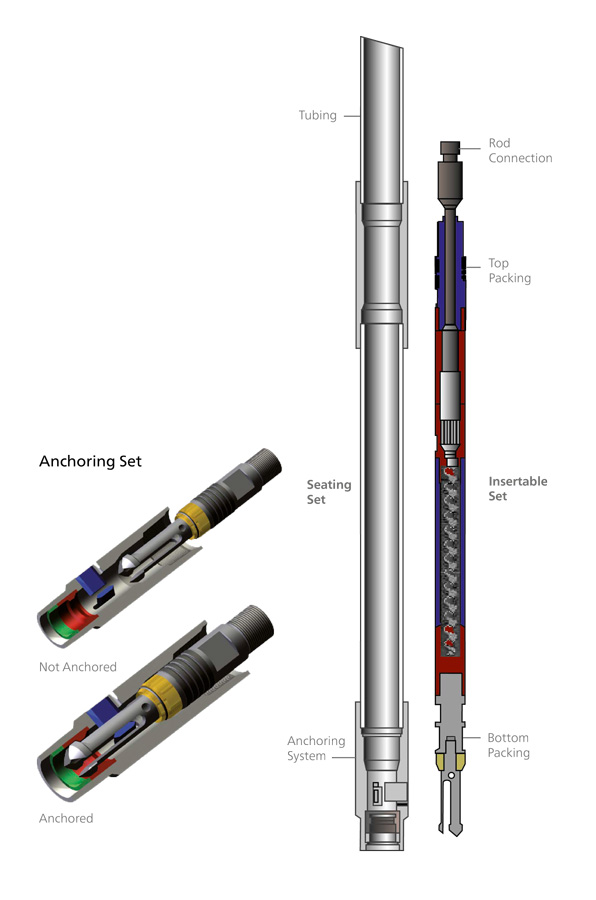

NETZSCH Insertable Progressing Cavity Pumps

The main feature of Progressing Cavity Pumps (rotor & stator) is their assembly inside the tubing. Thus, the pump is not connected to the production line but assembled inside it.

Applications

- Wells with low flow – the cost of the intervention makes the use of a normal pump economically not suitable

- Wells with a high frequency of interventions (independent of the flow)

- Flow range 1,3 to 491 bpd at 100 rpm

- Pressure range 100 to 240 bar

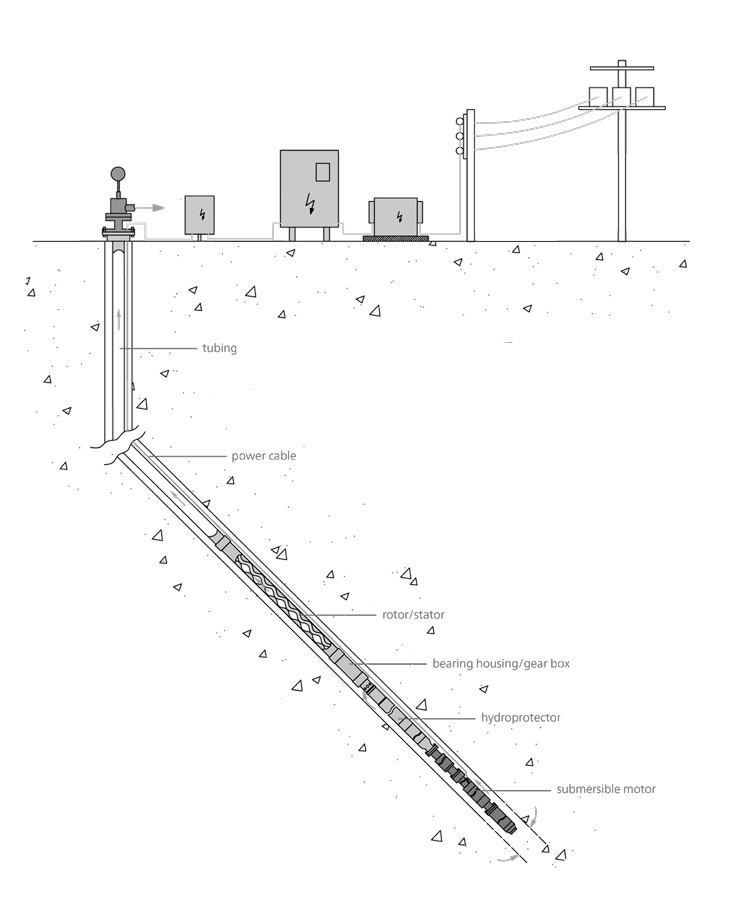

NTU Progressing Cavity Pumps

Produced with steel tube conform with the same internal geometry as the stator (helical). Thus the elastomer has a uniform wall and produces even distribution of the elastomer. The main NTU pump feature is its lower operation and starting torque due to its lower swelling when exposed to temperature variations and chemically aggressive fluids.

Advantages

- Ideal for chemical fluids with high aggresivity

- Lower starting torque

- Higher pressure capacity per stage

- Easier to assemble in wells with deviations

- Easy installation and transport

- Shorter pump length

- Lower hysteresis

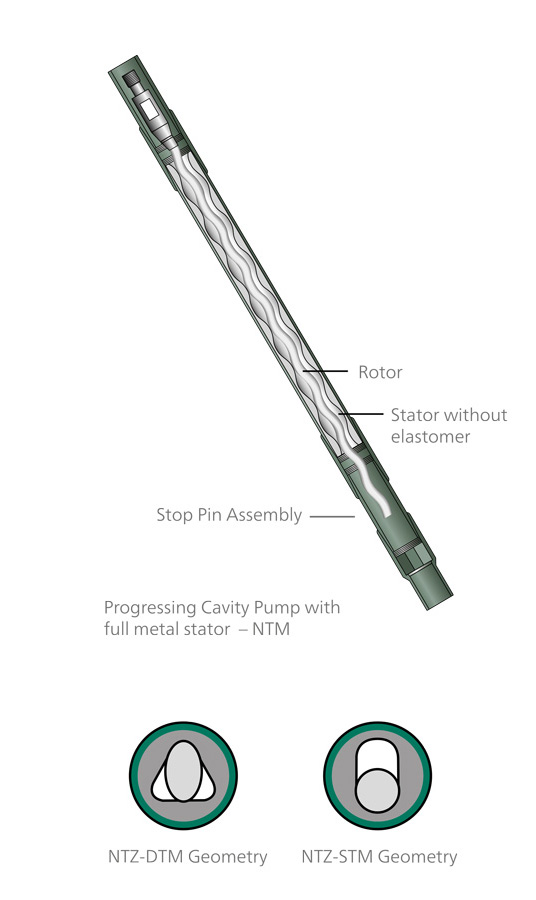

NTM Progressing Cavity Pump

- Maximum flexibility in the perspective of viscosity andtemperature

- No chemical attack on the elastomer

- Perfectly suited in combination with thermal treatment of the wells

Advantages

- Short pump length

- Lower starting and operational torque

- Longer run life under severe fluid conditions

- Less influence due to temperature and chemicals

- Easier to assemble in wells with deviations

- Lower hysteresis

- Better heat dissipation