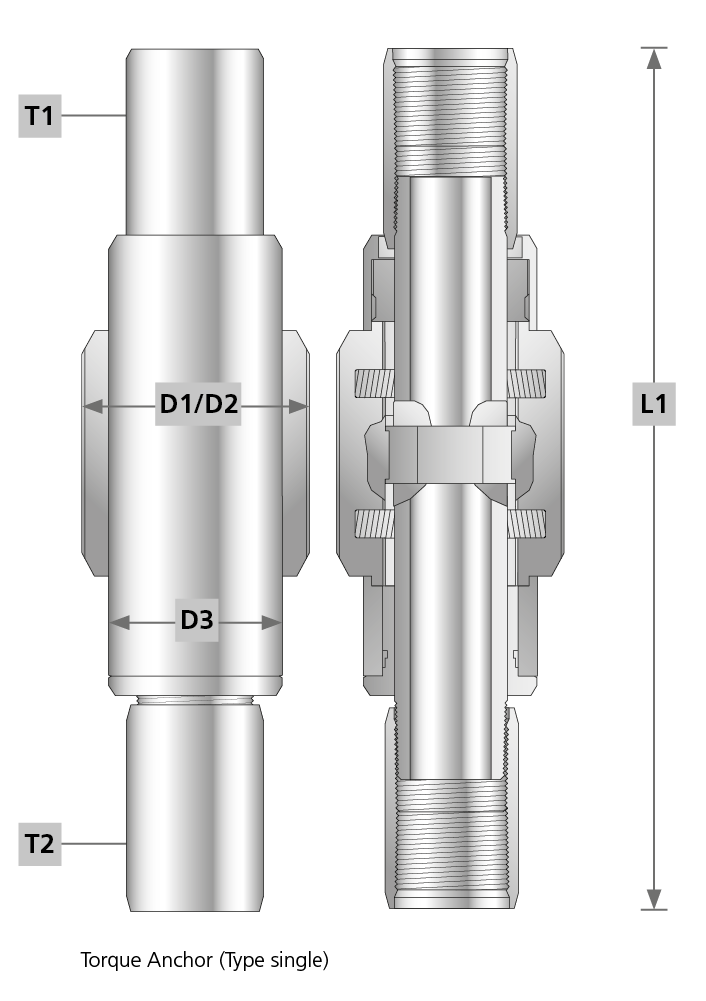

Torque Anchor

Torque anchor is used to take the reactive torque given by the friction between the rotor and the stator of the helicoidal pump with progressing cavities, to prevent the tubing from unscrewing. It is mounted under the pump.

The blades are permanently pushed and kept in touch with the well casing wall by means of helicoidal springs. The oil pumped passed through the central hollow shaft on to which the cams are mounted.

When the tubing rotates clockwise, the anchoring blades bite into the casing wall whenever a reactive torque is developed. Disengaging is done by rotating the tubing counter-clockwise from the surface.

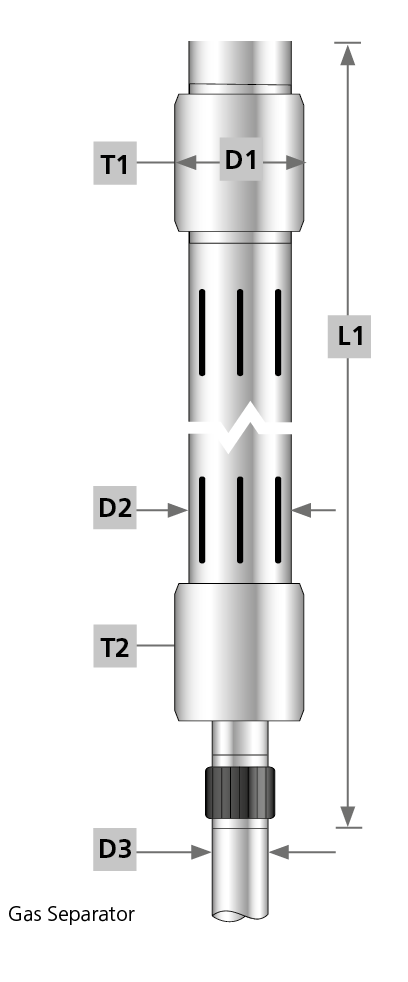

Gas separator

In general there are two options to install the Progressing Cavity Pump or suction pipe. Its installation can be either below or above the perforated interval. The preferred option to install the pump or the suction pipe is below the perforated interval, where the free gas will be separated in the annulus as a natural separation.

Depending on the area in the annulus, different volumes of gaseous liquid can be separeted. In the separation process the gas percolates upwards through the liquid column with a minimum speed of 550 m/h. It is obvious that higher volumes of gaseous fluid can be handled when the separation area is increased.

As long as downward fluid velocity does not exceed the separation velcity of the gas, no gas, or only a minimum amount of gas will pass through the pump. If the sump volume under the perforation is not sufficient, the Progressing Cavity Pump or suction pipe has to be installed above the perforation. For this case we recommend to integrate the mechanical gas separator as a part of the pump unit since the two fluids (gas and water) move upward.